Type of Pool:

Concrete – Commercial Pool

Situation:

The pool cleaner noticed that suction was not as strong as it used to be, which caused difficulty when cleaning the pool. There wasn’t significant water loss, so the customer didn’t suspect a large leak.

Solution:

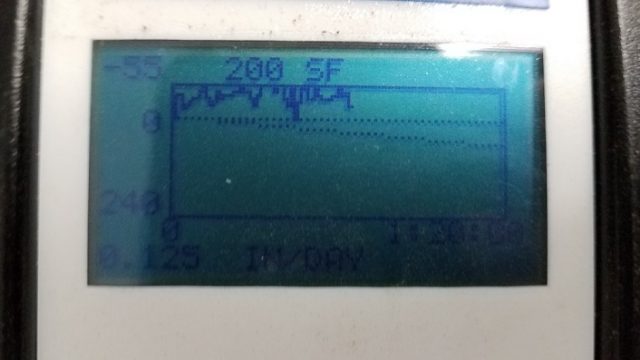

We started by shutting the pump off and running a static dye test using Dye Testing Cones. The line that included all five skimmers did not pass the static dye test, which indicated that there was a leak somewhere in that line. We then moved on to running a water pressure test on the line. The pool equipment was about 250 feet away from the pool, so it took a long time to build up pressure. Once pressure was built up, it dropped quickly, confirming that there was a leak in the pipe.

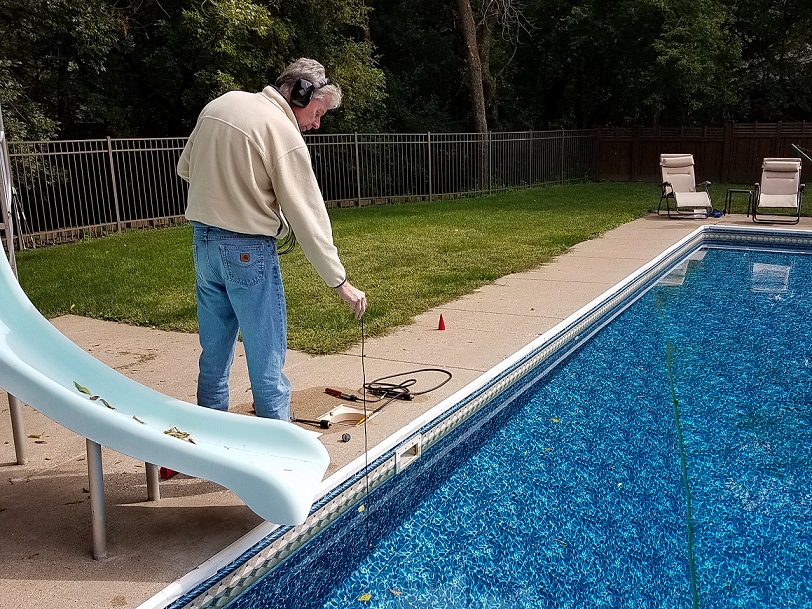

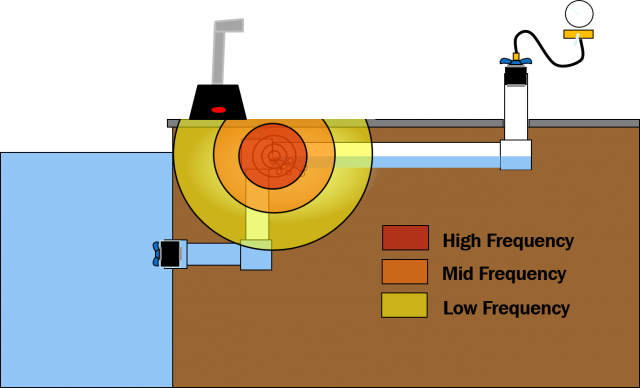

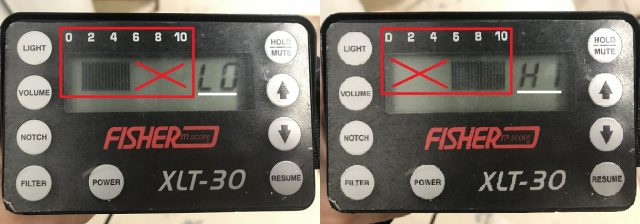

To locate the leak, we needed to get pressurized air to escape through the leak into water saturated soil. This makes the telltale bubbling sound that can be picked up by our Fisher listening device. To ensure that air reached the leak, we attempted to purge all the water from the line by inducing air. But, because the plumbing run was so long, it was hard to be certain that all the water had been purged. When we tried inducing air into the line from one of the skimmers we heard the leak noise in several areas along the plumbing run. Noise in several spots can indicate that there are multiple leaks, but could also be caused by low spots in the plumbing where the induced air is traveling through standing water still in the pipe. This is most likely to happen when inducing air from the low end of the plumbing.

Changing where the air pressure is being induced from can help rule out low spots and pinpoint the leak location. In this case, since we heard multiple leak noises, we changed to inducing pressure through a different skimmer on the other side of the pool. When air was induced from this skimmer, we heard a leak noise on this side of the pool but there was no longer a noise on the other side. The only place that made a leak noise from both induction points was between the two skimmers. So, that place was the most likely leak location. To verify that there wasn’t a leak farther down the line toward the equipment, we switched the induction point to a final location in the pump house. This caused a noise in a new location between the pool and the pump house as well as in the previous place between the skimmers. Since there was only one place where a leak noise was heard from all three induction points, we determined that was the leak location.

Because we were unable to get all the water out of the line there were also misleading sounds caused by air traveling through water trapped in low spots of the plumbing. By comparing leak noise locations as we changed the induction points, we could decipher which noise was the leak noise and which noises were false positives. Under pressure, air will only travel as far as it must in order to escape through the leak, so the low spots in the plumbing did not make noise unless they were between the induction spot and the leak location.

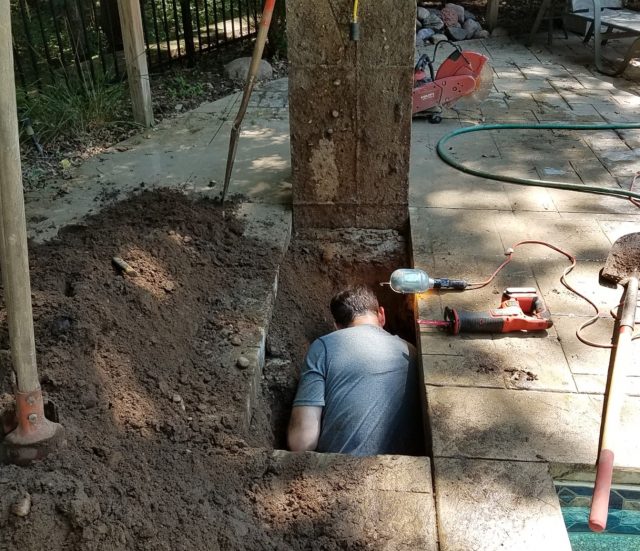

The extra listening time paid off – once the concrete was cut, we could see that our leak location was spot on! During the repair the lines were pressure tested to ensure that the other noises we had heard were not also leaks. While inducing air from multiple locations takes time, it’s still faster and more accurate than other methods that require you to fish equipment through the plumbing lines. Plus, due to the long plumbing run a camera wouldn’t have been able to reach the entire line and the amount of tracer gas needed to fill the line would have been expensive.

Highlights:

- Pressurized air escaping into water saturated soil makes a clear noise that can be accurately located with a listening device.

- Once pressure is built up, air in a pipe will only travel as far as it must to reach the leak, not further.

- Changing induction points can help rule out false noises from water stuck in low spots of the plumbing.